Motorcycle Parts New Zealand Specialists Fundamentals Explained

Table of ContentsGetting The Motorcycle Parts New Zealand Specialists To WorkMotorcycle Parts New Zealand Specialists - Questions9 Easy Facts About Motorcycle Parts New Zealand Specialists ShownThe Best Guide To Motorcycle Parts New Zealand SpecialistsThe Best Guide To Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists - The FactsThe smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking AboutGetting My Motorcycle Parts New Zealand Specialists To Work

Get to out to one of our specialists today.CNC machining technology is swiftly coming to be the focal point of several production processes around the globe as a direct result of its lots of benefits over other methods. Additionally, the markets that make motorbikes have jumped on board with this pattern. One of the most innovative companies are now creating their engine elements and wheels making use of machining techniques originally created for motorcycle components.

You might be wondering why we make use of. Now that we have your attention allow us clarify the reasoning behind this modern-day development in the motorcycle production sector.

Everything about Motorcycle Parts New Zealand Specialists

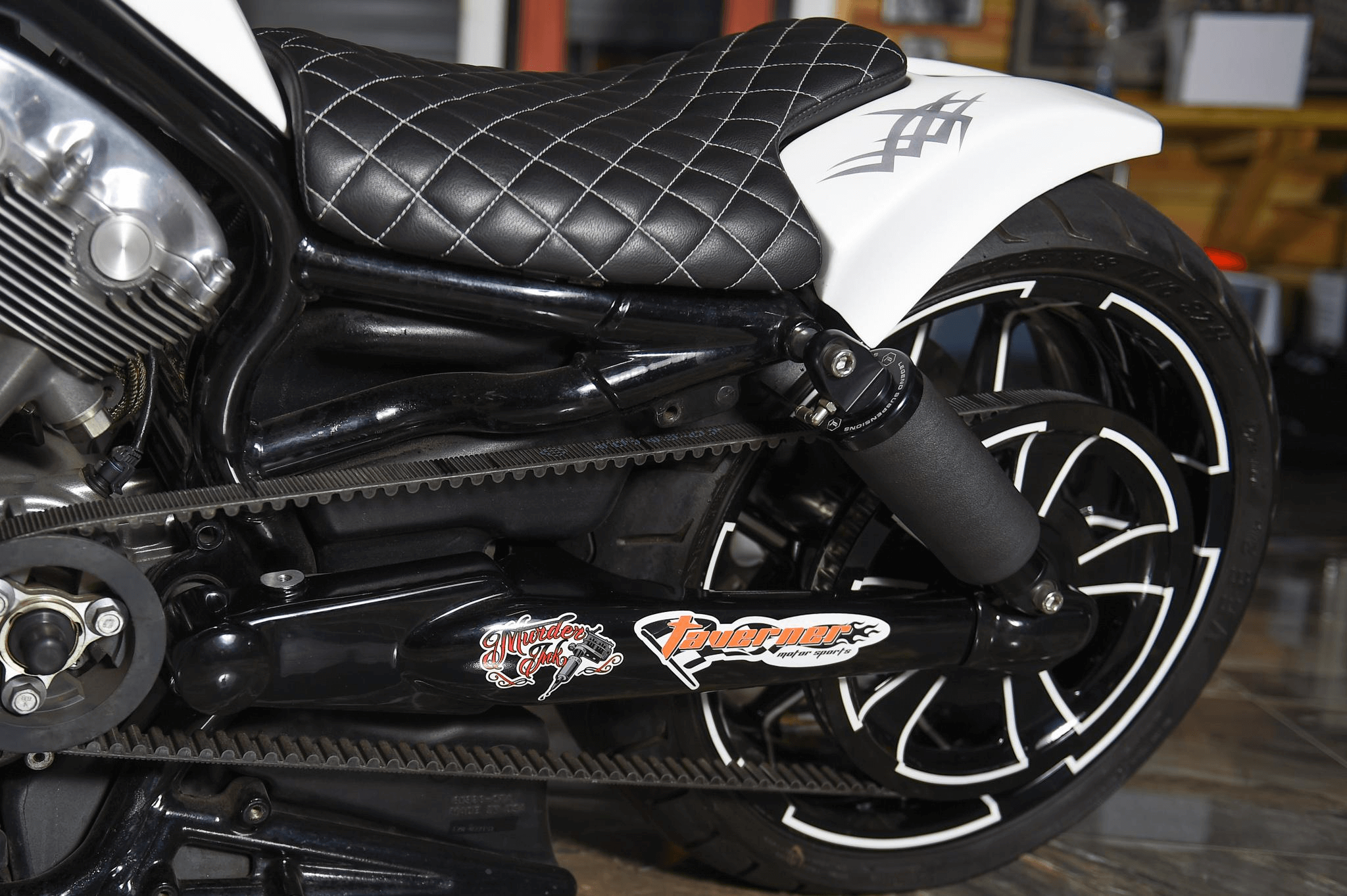

In enhancement, you have complete control over the appearance of the parts, also down to the minute details. Sometimes, motorcyclists may decide to spruce up their adventure by installing aftermarket elements or changing the bike's transformation.

The 4-Minute Rule for Motorcycle Parts New Zealand Specialists

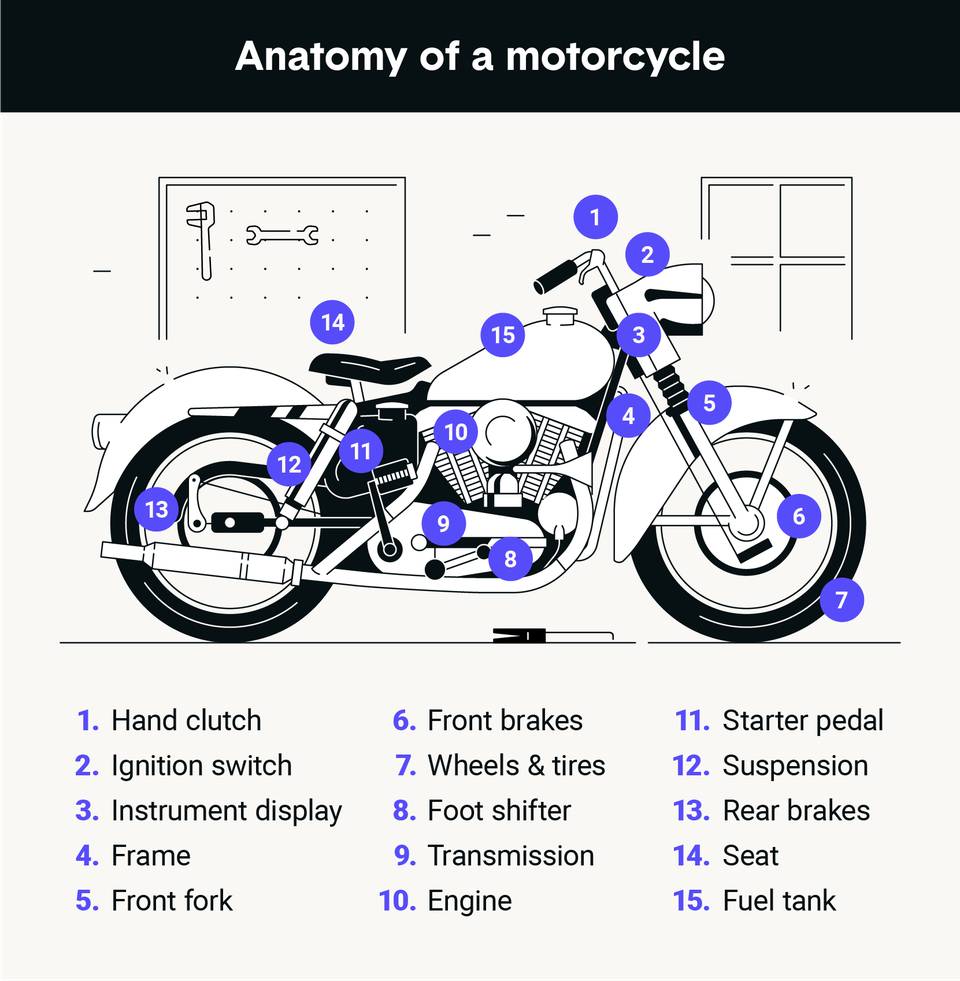

CNC machining might be made use of to make virtually all of a bike's steel and plastic parts. To proceed, we'll review numerous machined components for motorcycles.

Milling procedures are made use of to obtain the preferred degree of wheel modification. One more element of the motorcycle that may be personalized is the tires.

The Single Strategy To Use For Motorcycle Parts New Zealand Specialists

When it comes to a lorry (or a motorbike), the most crucial component is the engine. Numerous people point to it as the "heart" of the car. On the other hand, the camshaft, the cylinder head, and the pistons have a tendency to be complex and require designs with a high degree of precision.

Lighting is another facility element of modification. Usage just top quality items, nonetheless, since these lights are vital for the security of motorcyclists and various other chauffeurs or people on the road, especially in the evening. Bike headlights have three major components: the light bulb, or light source, the lens, and the housing. In particular, we customize the lens and the real estate.

Milling procedures with a perfect coating would certainly cause the lenses having a reflective top quality that is similar this page to that of a mirror. The cover, on the other hand, is not composed of breakable products; rather, it is built out of difficult polymers that can be machined right into even more detailed patterns.

What Does Motorcycle Parts New Zealand Specialists Mean?

They often have sophisticated geometries with a riches of minute information. Bike manufacturers frequently cast these components, but just for the production of bespoke components. CNC machining is the method of option when creating one-of-a-kind pieces. Machining on 5 axes in today's globe is the methods whereby any design shape may be recognized.

Pick Runsom for pop over to this site your customized motorcycle components! We have the capability to fabricate difficult and stylish parts making your motorcycle matchless.

Right here are a few examples of metals usually utilized in motorbike part machining. Aluminum is the key material made use of by business specializing in creating custom-made bike parts to create many of these parts. In the past, we would build our engines out of actors iron. On the various other hand, light weight aluminum is swiftly coming to be the product of selection, partially because of the reality that it is more light-weight.

Zinc refers to one more metal that is really light in weight and has fantastic machining top qualities due to its high mechanical stamina. This product may be developed into almost any form and keeps its measurements well. Also mission-critical components that need a high degree of accuracy may gain from their use.

Motorcycle Parts New Zealand Specialists Can Be Fun For Anyone

An additional steel that sees hefty usage in the production of CNC-customized parts is magnesium. It is among the lightest metals that are now accessible and has exceptional machinability attributes and stamina appropriate with its low weight. Among the disadvantages of magnesium is that its dirt might conveniently capture fire.

Their most common use in producing various motorcycle parts is bolts, such as screws and screws. Their reduced sensitivity to oxidation and corrosion makes them optimal for this usage.

The Ultimate Guide To Motorcycle Parts New Zealand Specialists

It seems that CNC transforming and crushing are the foundational processes. In enhancement, it needs maintaining bars of product, most frequently plastic or steel, in setting and then turning a cutting tool to remove areas of the material as the product is turned.

These approaches are equally crucial and produce elements with high accuracy and constant top quality. They are respectively: grinding, laser cutting, and boring. The term "surface coating" describes post-processes basics after the preliminary machining phase. Motorcycle Parts New Zealand Specialists. The procedures help enhance the total quality of the machined motorcycle parts. Below are the quick introduction, benefits and drawbacks of five surface treatment techniques.

Things about Motorcycle Parts New Zealand Specialists